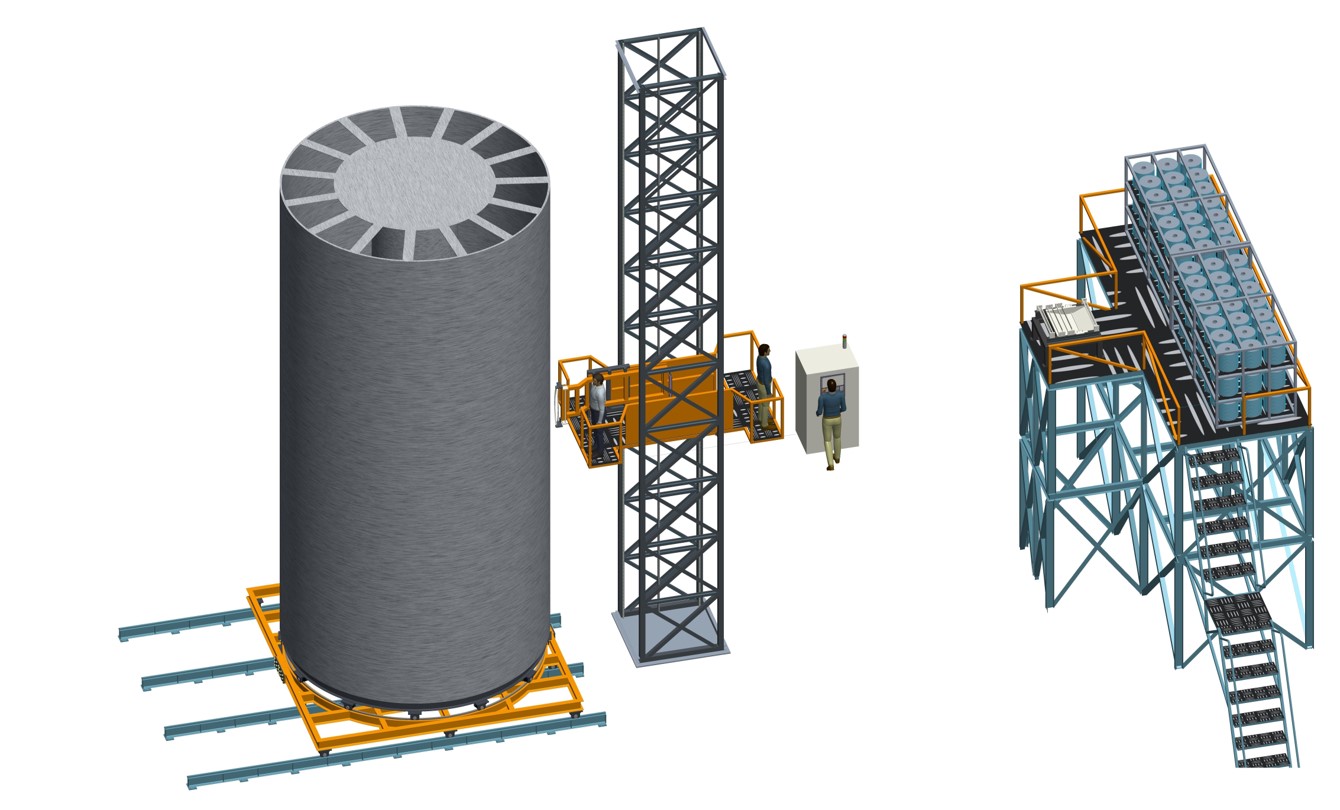

Space-Efficient Precision for Advanced Composite Manufacturing

Specialized equipment for precise fiber winding

Mandrels positioned vertically for smooth, even fiber distribution

Advanced systems for consistent tension throughout winding

Precise control over speed, tension, and layering

Optimized for efficient composite manufacturing

A vertical winding machine is a specialized piece of equipment used in the fiber and textile industries for winding fibers onto mandrels or other types of cores. The vertical design means that spools are oriented vertically during winding, which helps maintain tension and prevents tangling or overlapping of fibers.

Advantages of our vertical winding technology

The vertical design is more space-efficient in factory settings compared to horizontal alternatives.

Precise control over tension and winding parameters ensures high-quality wound products.

Vertical orientation prevents tangling and overlapping of fibers during winding.

Discover how our vertical winding machine can enhance your production efficiency and deliver superior composite components.